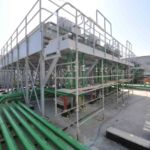

Khor al Zubair Power Station in Iraq involves two existing ALSTOM 13D gas turbines, having an 81.2MW capacity each. DEP scope was to provide a full detailed design study and shop drawings for a cooling system that would cool the inlet air to the gas turbines to increase their efficiency. This specialized technology enables the government to increase the production without interruption of the operation. The design included 3D mechanical model for the mechanical plant rooms and structural design for the steel structure for the filters and piping support. This project consists of installing two chiller plants, composed of 2 chillers each, generating a total of 7000 TR cooling water. These water cooled chillers, will provide the necessary chilled water to the “filter houses”, where the turbines inlet air will be cooled to reach a temperature of less than 15deg.C at the turbine suction side.

Scope of Work

MEP Design of the project

- Location: IRAQ

- Year: 2016

- Client: Ministry of Electricity